No. 200 Gaoxin RD, Shanghua St, Lanxi, Zhejiang, P. R China

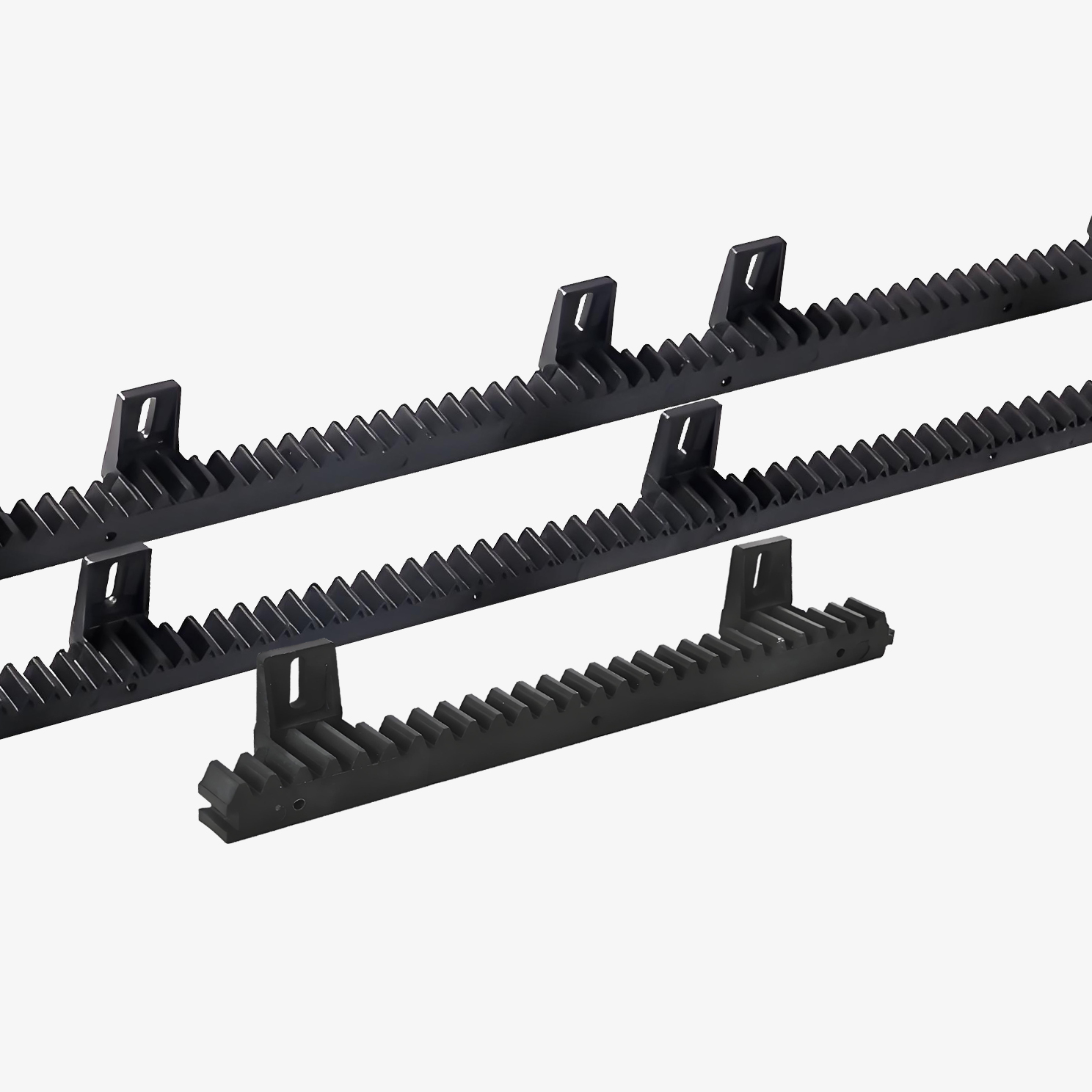

The High Precision Straight Teeth Rack Pinion Gear is a critical compo...

See DetailsThe rack should be installed straight: Use a level to ensure that the rack is installed straight, otherwise it will affect the smoothness of the sliding door.

The rack connection should be firm: Use suitable connectors to firmly fix the rack to the door body and track.

The gear meshing should be appropriate: The meshing clearance between the gear and the rack should be moderate. Too tight will increase friction, and too loose will cause slipping.

Lubrication and maintenance: After installation, apply lubricating oil on the rack and gear to reduce friction and noise.

The high precision stainless steel rack and pinion system is a critical component in various mechanical and automation applications, where accurate linear motion and resistance to environmental factors are required. This mechanical assembly, consisting of a linear rack and a rotating pinion, converts rotational motion into linear displacement. When manufactured from stainless steel and engineered to high precision standards, this system exhibits both durability and exceptional accuracy, making it ideal for demanding industrial environments.

One of the primary reasons for choosing a high precision stainless steel rack and pinion is its reliability in harsh conditions. Stainless steel offers resistance to corrosion, which is particularly valuable in sectors like food processing, pharmaceuticals, and marine engineering. In these industries, machines are frequently exposed to moisture, chemicals, or fluctuating temperatures. A high precision stainless steel rack and pinion maintains its performance without degradation over time, contributing to lower maintenance costs and extended equipment life.

In automation and robotics, the demand for accuracy and repeatability is high. A high precision stainless steel rack and pinion system ensures that motion control systems function smoothly and consistently. Its ability to deliver exact positioning is crucial for robotic arms, CNC machines, and laser cutting equipment. For instance, in CNC milling operations, even a minor deviation in linear motion can result in significant product defects. By using a high precision stainless steel rack and pinion, manufacturers can achieve the required tolerances and reduce scrap rates.

The medical device manufacturing sector also benefits from this technology. Equipment used in this field often demands not only precision but also cleanroom compatibility. The non-reactive nature of stainless steel makes the high precision stainless steel rack and pinion a suitable choice for such sterile environments. Additionally, the high-grade surface finish of these components reduces particulate generation, helping meet strict contamination control standards.

Another key application lies in transportation systems, particularly in rail and tram mechanisms where a high precision stainless steel rack and pinion can provide the necessary traction and control on steep gradients. Funicular railways, for example, rely on rack and pinion systems to ensure safe and smooth travel up and down inclined tracks. Stainless steel construction ensures that these systems continue operating effectively in outdoor environments subjected to rain, snow, and temperature fluctuations.

In aerospace, weight, durability, and precision are fundamental concerns. The high precision stainless steel rack and pinion plays a role in actuators and control systems, contributing to the fine-tuned movement of components within aircraft. The ability to withstand conditions while maintaining mechanical integrity is a crucial advantage in this context.

Similarly, in the field of renewable energy, such as solar panel tracking systems, the high precision stainless steel rack and pinion ensures accurate positioning of panels for energy capture. These systems must endure continuous outdoor exposure, making corrosion resistance and minimal maintenance essential. The use of high precision stainless steel rack and pinion systems allows for precise daily adjustments while maintaining long-term durability.

In architectural applications, such as automated facades or retractable structures, the high precision stainless steel rack and pinion allows for seamless operation with minimal visible wear over time. These aesthetic and functional systems often require discreet yet reliable mechanical movement, which stainless steel components provide efficiently.

Packaging machinery, which operates at high speeds and with tight tolerances, also benefits greatly from the implementation of a high precision stainless steel rack and pinion. Accurate motion control ensures that packages are handled consistently, errors and ensuring uniformity across production batches. The sanitary properties of stainless steel further make it suitable for packaging food and pharmaceutical products.