No. 200 Gaoxin RD, Shanghua St, Lanxi, Zhejiang, P. R China

The Multiple Specifications Rack Pinion Gear is a versatile mechanical...

See Details

Large gates are widely used in industrial sites, farms, warehouses, and commercial properties. These gates are often exposed to frequent movement, heavy loads, and outdoor environments. Behind their stable operation is the work of a Hinges Heavy Duty Gate Manufacturer, whose task is to provide hinge solutions that support weight, movement, and durability over time.

Heavy duty gate hinges are designed to carry substantial gate weight while allowing smooth opening and closing. A Hinges Heavy Duty Gate Manufacturer focuses on balancing load capacity with practical usability. The hinge must support the gate without sagging, while also reducing friction and wear during daily operation.

Unlike light residential hinges, heavy duty hinges are commonly used on steel gates, large wooden gates, and security fencing systems. Their performance directly affects how the entire gate system functions.

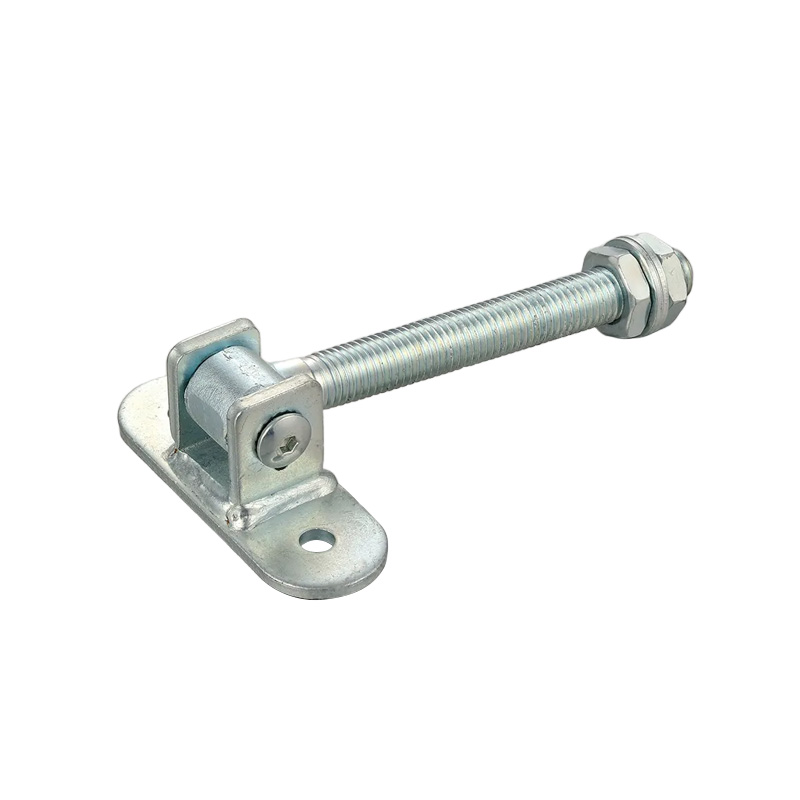

Gate size and weight vary depending on application. A Hinges Heavy Duty Gate Manufacturer considers factors such as gate width, material thickness, and installation method during the design stage. Some hinges are designed for welding, while others are bolted or adjustable.

Adjustability is often an important feature. In outdoor environments, ground movement or long-term use can cause alignment issues. Hinges with adjustable pins or plates help installers correct positioning without replacing the entire gate system.

Material selection plays a major role in hinge lifespan. A Hinges Heavy Duty Gate Manufacturer typically uses carbon steel, stainless steel, or alloy steel depending on load and environmental exposure. For outdoor gates, corrosion resistance is especially important.

Surface treatments such as galvanizing, powder coating, or zinc plating help protect hinges from moisture, dust, and temperature changes. These treatments also reduce maintenance frequency, which is a practical concern for industrial and commercial users.

The manufacturing process for heavy duty hinges involves cutting, forming, machining, and assembly. A Hinges Heavy Duty Gate Manufacturer ensures dimensional accuracy so that hinge components align properly during installation.

Load testing and movement testing are common quality checks. Hinges are often tested under simulated gate weight and repeated opening cycles to ensure stable performance. This helps reduce issues such as uneven movement or premature wear once the hinge is installed in real conditions.

Heavy duty gate hinges are used across many sectors. A Hinges Heavy Duty Gate Manufacturer supplies hinges for factory entrances, agricultural fencing, logistics yards, and security facilities. Each scenario has different requirements, such as higher load capacity, weather resistance, or compatibility with automation systems.

In some projects, hinges are integrated with automatic gate openers. In these cases, smooth movement and consistent alignment are especially important to avoid strain on motors and control systems.

Not all gates follow standard designs. A Hinges Heavy Duty Gate Manufacturer often provides customized hinge solutions based on drawings or project specifications. Custom options may include pin diameter, mounting plate size, opening angle, or surface finish.

This level of flexibility helps contractors and system integrators match hinges to unique gate designs without redesigning the entire structure.

Proper installation and basic maintenance help extend hinge service life. Hinges designed by an experienced Hinges Heavy Duty Gate Manufacturer are typically easy to lubricate and inspect. Periodic checks help prevent issues such as misalignment or excessive friction.

Simple maintenance routines reduce downtime and keep gates operating smoothly in demanding environments.

A Hinges Heavy Duty Gate Manufacturer supports the stability and reliability of large gate systems through thoughtful design, material selection, and manufacturing control. By focusing on real-world usage, load requirements, and installation needs, manufacturers provide hinge solutions that suit industrial, agricultural, and commercial applications. Understanding these factors helps buyers select hinges that match both functional and environmental demands.