No. 200 Gaoxin RD, Shanghua St, Lanxi, Zhejiang, P. R China

The multiple sizes high precision rack pinion gear system is an essent...

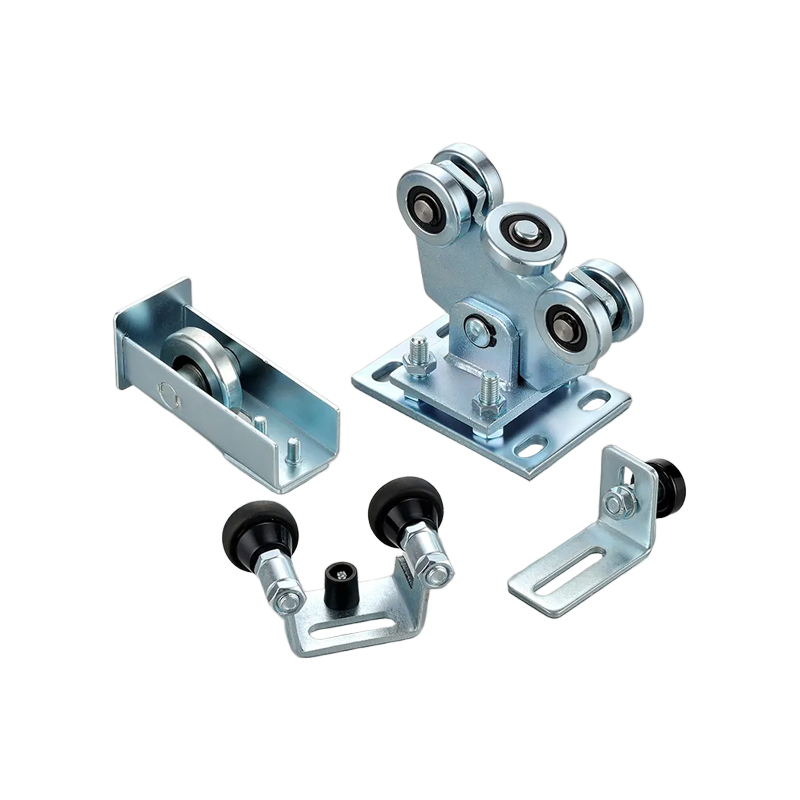

See DetailsV groove metal wheels are widely employed in sliding gate systems due to their ability to provide stable, guided movement along corresponding V-shaped tracks. Their design facilitates low rolling resistance and precise tracking, especially in applications where alignment and load handling are critical.

Load-Bearing Capacity Considerations

The load-bearing capacity of a V groove wheel depends on several interrelated factors: the diameter of the wheel, the type and size of the bearing, the material used, and the design of the axle or mounting assembly. Larger wheels with wide treads and high-grade bearings can support more weight and better withstand impact from uneven surfaces. In heavy-duty settings, each wheel is often rated to carry several hundred kilograms. Engineers typically calculate total gate weight and divide it by the number of support wheels, while also including a safety factor to account for dynamic loads during movement or shifting.

Material Selection

The choice of material significantly influences the wheel's performance, wear resistance, and longevity. Common materials include:

Cast Iron: Known for its rigidity and durability, cast iron is often used in industrial gates. It resists deformation under heavy loads but may be brittle under shock.

Steel (Carbon or Stainless): Offers a strong balance between strength and impact resistance. Stainless steel is preferred for outdoor use due to its corrosion resistance.

Nylon or Polyurethane-Coated Steel: These hybrid materials reduce noise and vibration but are typically suited for lighter loads or residential gates.

High-precision machining and tight tolerances are essential during manufacturing to ensure a consistent V groove profile, which directly affects track engagement and rolling efficiency. When paired with quality tracks and proper alignment, V groove metal wheels provide long-term reliability even in demanding conditions.

Heavy metal gate hinges must support substantial weight while allowing for repeated opening and closing cycles with minimal wear. A crucial part of producing durable and smooth-operating hinges lies in the surface grinding process, which refines the finish and dimensional accuracy of hinge components.

Purpose and Benefits of Surface Grinding

Surface grinding is used to achieve a flat, smooth, and uniform surface finish on hinge plates, pins, and knuckles. This process improves the mechanical function of the hinge by reducing friction between moving parts, ensuring tighter fits, and improving contact between welded or bolted surfaces. For large or heavy gates, smooth movement is essential—not just for ease of operation, but also to reduce stress on supporting structures and prolong the hinge's service life.

Process Overview

The surface grinding process typically involves the following steps:

Preparation: Raw hinge components, such as cut steel plates or forged sections, are cleaned and clamped onto a magnetic or mechanical fixture.

Grinding: A rotating abrasive wheel is passed over the surface of the hinge part in controlled passes. The process removes a very thin layer of material (often measured in microns), which helps achieve high dimensional precision.

Cooling and Lubrication: To avoid thermal distortion or surface burns, coolant is applied continuously during grinding. This keeps temperatures in check and aids in chip removal.

Quality Control: After grinding, components are inspected for flatness, parallelism, and surface finish using gauges and micrometers.

Types of Surfaces Ground on Hinges

Mounting Plates: Flat grinding ensures a secure, flush fit when mounted to gates or posts.

Knuckle Interfaces: Smooth rotation requires tight tolerances in the pin and knuckle surfaces.

Welded Edges: Grinding may also be used to clean up weld areas for aesthetic and structural consistency.

Proper surface grinding enhances both the appearance and the operational performance of gate hinges. In high-use or high-weight applications, precision-ground hinges reduce wear, prevent misalignment, and contribute to the overall safety and reliability of the gate assembly.