No. 200 Gaoxin RD, Shanghua St, Lanxi, Zhejiang, P. R China

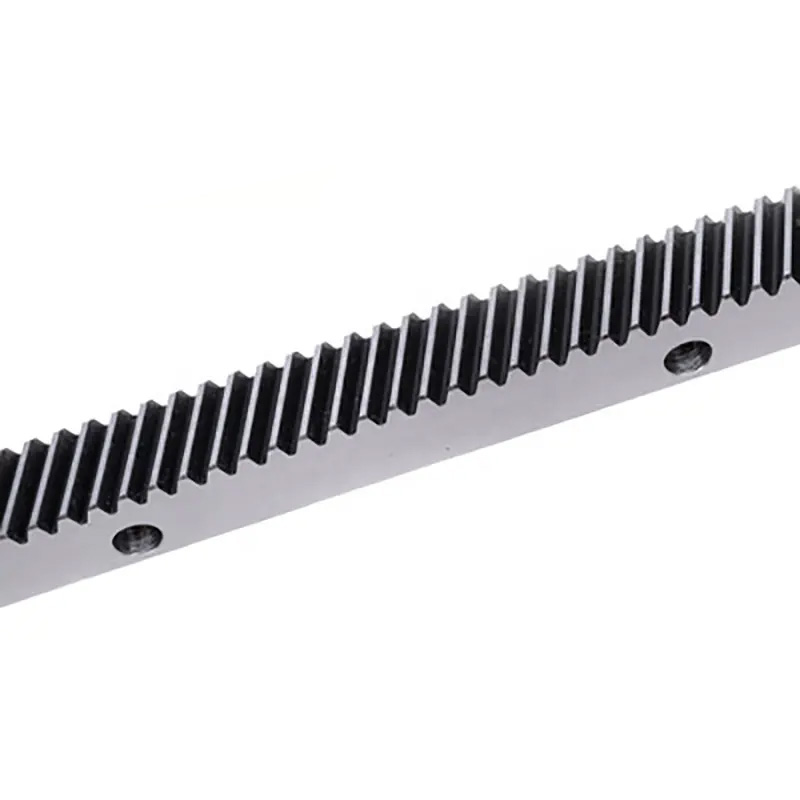

The Surface Heat Treatment Rack Pinion Gear is a precision-engineered ...

See DetailsThe evolution of the Aluminum Large CNC Straight Gear Rack and Pinion represents a significant advancement in precision motion control systems. This component, commonly used in industrial automation, robotics, transportation systems, and specialized machinery, has gone through a series of technological developments that mirror broader trends in manufacturing, materials engineering, and computer numerical control (CNC) machining. Understanding the history of the Aluminum Large CNC Straight Gear Rack and Pinion sheds light on its current applications and offers insights into future directions in mechanical motion systems.

The concept of rack and pinion mechanisms dates back to ancient engineering, where wooden or bronze components were used to convert rotational motion into linear movement. However, the integration of aluminum and CNC technology into this system did not occur until much later. The early 20th century saw increasing industrial demand for more efficient linear motion solutions, which led to the widespread use of steel rack and pinion mechanisms in automotive steering systems and machine tools.

It was not until the mid-20th century that aluminum began to be explored as a viable alternative to steel in mechanical systems. The development of stronger aluminum alloys opened new possibilities in aerospace and automotive industries, which required components that were both lightweight and corrosion-resistant. These properties laid the groundwork for the future development of the Aluminum Large CNC Straight Gear Rack and Pinion.

During the 1970s and 1980s, the introduction of CNC machining dramatically transformed the manufacturing landscape. CNC technology made it possible to produce gear components with higher accuracy and repeatability than manual machining methods. As industries demanded tighter tolerances and faster production cycles, CNC machining became the standard for gear manufacturing. This technological leap was instrumental in the refinement and mass production of the Aluminum Large CNC Straight Gear Rack and Pinion, which required precise tooth geometry and consistent linear accuracy.

The growing use of aluminum in the 1990s, particularly in industrial automation and high-speed applications, increased interest in the Aluminum Large CNC Straight Gear Rack and Pinion. Engineers recognized that aluminum offered a favorable strength-to-weight ratio and machinability, which allowed for the creation of large-scale gear racks without excessive weight. This feature was particularly useful in automated equipment and robotic systems where dynamic movement and reduced inertia were critical.

The turn of the 21st century marked a period of optimization for the Aluminum Large CNC Straight Gear Rack and Pinion. With advancements in CAD/CAM software, finite element analysis, and CNC machine capabilities, manufacturers began to tailor the geometry and material properties of gear racks for specific performance requirements. Anodized coatings, hybrid material designs, and improved thermal expansion control were introduced to address application-specific challenges.

Today, the Aluminum Large CNC Straight Gear Rack and Pinion is widely utilized in applications where both precision and light weight are necessary. For example, in semiconductor manufacturing equipment and laboratory automation systems, the combination of aluminum and CNC machining allows for cleanroom-compatible, non-corrosive motion control components. In stage machinery and large-format printers, the Aluminum Large CNC Straight Gear Rack and Pinion provides smooth and accurate linear motion with minimal noise and vibration.

One of the important milestones in the development of the Aluminum Large CNC Straight Gear Rack and Pinion was the incorporation of modular design features. This allowed gear racks to be manufactured in standardized segments, which could be easily assembled or replaced without requiring custom fabrication. This modularity greatly reduced installation and maintenance time and made the system more accessible to a broader range of industries.