No. 200 Gaoxin RD, Shanghua St, Lanxi, Zhejiang, P. R China

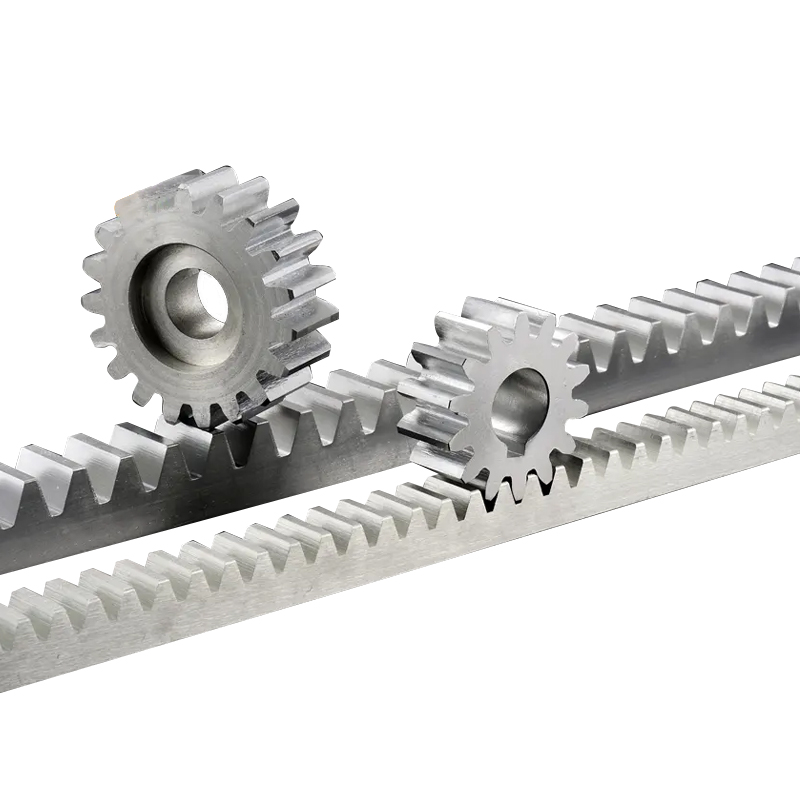

The Stainless Steel Rack Pinion Gear for Sliding Motors is a high-prec...

See Details

Gears and gear racks are fundamental components in precision movement systems, offering reliable and efficient methods for converting rotational motion into linear movement. These mechanical elements are widely used in a variety of applications, from industrial machinery to robotics and automotive systems, where accurate and controlled movement is required. Understanding how gears and gear racks function together to achieve precision is essential for anyone looking to implement or improve these systems.

A gear is a rotating mechanical component with teeth that mesh with another gear or gear rack to transmit motion and torque. When paired with a gear rack, which is a flat bar with teeth cut into it, the gear provides the rotational motion, and the rack converts this motion into linear motion. This combination allows for the movement of objects along a specific path with great accuracy, making it an ideal solution for applications requiring precise positioning or movement control.

One of the key roles of gears and gear racks in precision movement systems is to provide smooth and accurate motion. Gears, with their carefully machined teeth, create a stable connection that minimizes the possibility of slippage, ensuring that motion is transmitted precisely from one part to another. The teeth of the gear mesh perfectly with those of the gear rack, which ensures that the linear movement of the rack remains consistent and reliable over time. This precision is crucial in systems such as CNC machines, where even small errors can cause faulty operations.

Another significant role of gears and gear racks is their ability to handle high loads while maintaining stability. When gears mesh with a gear rack, the force is distributed evenly across the teeth, preventing excessive wear and ensuring that the system operates smoothly under heavy loads. This characteristic is especially important in industries such as manufacturing, where large and powerful machines require reliable, load-bearing components. The strength of gears and gear racks allows them to handle these demands without compromising the accuracy or efficiency of the movement system.

In addition to providing accurate and stable motion, gears and gear racks offer the advantage of versatility in system design. They can be customized in terms of size, material, and tooth configuration to meet the specific needs of different applications. For example, gears can be designed with different pressure angles or tooth profiles to achieve the desired torque output or motion speed. Similarly, gear racks can be manufactured with varying tooth sizes to suit specific linear movement requirements. This flexibility makes gears and gear racks suitable for a wide range of industries and applications, from automotive steering systems to robotic arms.

The integration of gears and gear racks also helps simplify the design and construction of precision movement systems. Instead of relying on complex and expensive hydraulic or pneumatic systems for linear motion, gears and gear racks provide a mechanical solution that is often more cost-effective and easier to maintain. Their durability and longevity further contribute to the efficiency of the system, as gears and gear racks can operate for extended periods with minimal maintenance when properly lubricated and cared for.

Gears and gear racks play an essential role in precision movement systems by converting rotational motion into linear movement with great accuracy and reliability. Their ability to handle heavy loads, provide smooth motion, and offer design flexibility makes them valuable components in a wide variety of industries. By using gears and gear racks, engineers can create systems that deliver precise, controlled movement, ensuring performance in applications where precision is critical. Whether in robotics, machinery, or transportation systems, gears and gear racks are key elements in ensuring the accuracy and efficiency of movement systems.