No. 200 Gaoxin RD, Shanghua St, Lanxi, Zhejiang, P. R China

The Smooth Surface High Precision Rack Pinion Gear is a high-performan...

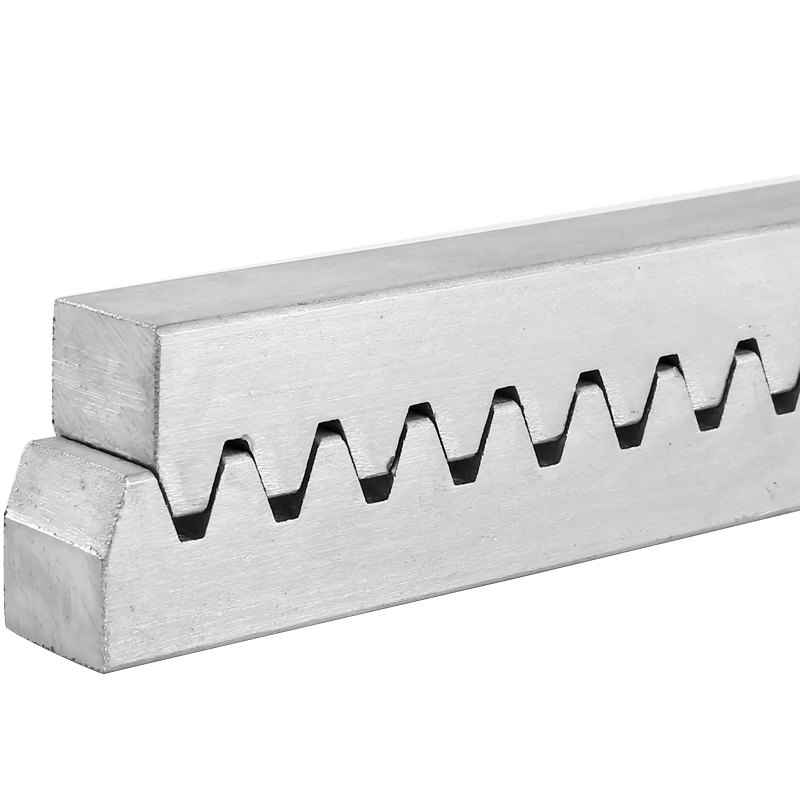

See DetailsThe Straight Gear Rack for Automatic Doors is a key component in the mechanical systems that control the opening and closing of automated entrances. Used in commercial buildings, hospitals, transportation terminals, and high-traffic areas, these racks enable reliable linear motion when paired with a pinion and a motorized drive.

One of the main reasons for using a straight gear rack in automatic doors is precise control of door movement. Compared to belt- or chain-driven systems, a gear rack provides consistent linear travel, which is essential for maintaining the timing, alignment, and security of door panels. The straight profile ensures that the movement is predictable, reducing wear on connected parts.

Durability and low maintenance are also important. The Straight Gear Rack for Automatic Doors is typically made from steel or aluminum with surface treatments to resist corrosion and abrasion. In many cases, hardened teeth or polymer overlays are used to reduce noise and improve service life.

Additionally, these racks support compact and space-efficient designs, allowing integration into slim door frames without requiring large housings. This is particularly important in retrofitting projects or locations where minimal visual intrusion is desired.

The material selection of a Cylindrical Straight Gear Rack significantly impacts its mechanical performance, longevity, and compatibility with various applications. These gear racks are used in machine tools, automation equipment, and transportation systems where cylindrical designs offer specific integration or load-handling benefits.

A primary consideration in material selection is the load-bearing capacity. For heavy-duty applications, materials such as alloy steel (e.g., 4140 or 4340) are chosen for their high tensile strength and resistance to fatigue. These steels may be heat-treated to enhance hardness, especially along the gear teeth, which are subject to repeated meshing.

For moderate-load or corrosion-prone environments, stainless steel (such as 304 or 316) is often preferred. Though not as strong as hardened alloy steel, stainless steel provides a good balance of strength, machinability, and corrosion resistance. It is commonly used in food processing, marine, or chemical environments.

When weight is a concern or the load is light, aluminum may be selected. Although aluminum has a lower strength than steel, it offers machinability and is resistant to rust. In such cases, the gear rack is often paired with plastic or low-friction pinions to extend its operational life.

Additionally, plastic cylindrical gear racks, typically made from nylon or acetal, are suitable for low-load, quiet operation applications such as robotics or consumer electronics.

The Lightweight Rack and Pinion system is increasingly used in applications where reducing weight is crucial without compromising the system’s ability to deliver precise linear motion. These systems are especially valuable in sectors such as robotics, aerospace components, automated medical devices, and portable machinery.

The main advantage of a lightweight rack and pinion lies in its ability to improve motion efficiency while mass. In robotic arms or mobile automation units, unnecessary weight can reduce speed, increase energy consumption, and accelerate component fatigue. By using materials such as aluminum, engineering plastics, or composite polymers, manufacturers can produce rack and pinion systems that are easier to handle, faster to accelerate, and more efficient.

In many cases, a lightweight rack is fabricated from aluminum alloys, which provide a good balance of structural integrity and reduced mass. When matched with properly designed lightweight pinions made from either hardened polymers or aluminum, the system maintains alignment and torque transmission for low to moderate loads.