No. 200 Gaoxin RD, Shanghua St, Lanxi, Zhejiang, P. R China

The Gearbox Steering Rack Pinion Gear is a fundamental component in mo...

See Details

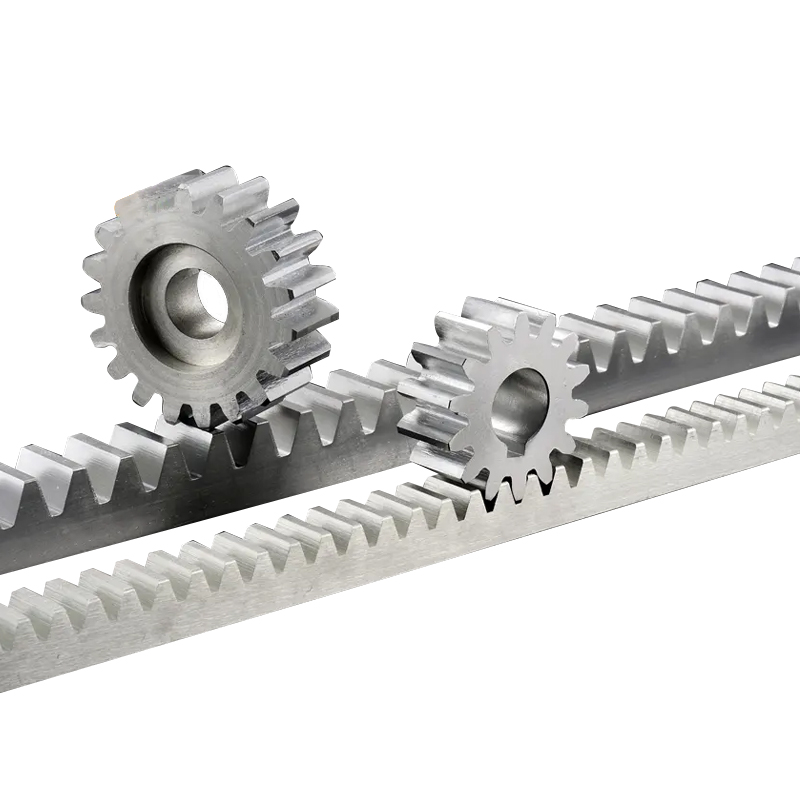

Mechanical systems often rely on components that convert rotational motion into linear motion. Among these, the gear and gear rack combination is widely used in industrial machinery, robotics, and automation equipment.

Understanding Gear and Gear Rack Systems

A gear and gear rack system consists of a rotating gear, known as a pinion, and a linear toothed bar, the rack. When the pinion rotates, its teeth engage with the rack's teeth, producing linear motion along the rack's length. This simple mechanism allows precise control of movement and can transmit force over varying distances.

Unlike belt or chain drives, the direct engagement between gear teeth reduces slippage, providing consistent and predictable motion. This reliability is one reason why gear racks are preferred in applications requiring precise positioning.

Reducing Energy Loss

One key advantage of using a gear and gear rack is the reduction of energy loss. Mechanical systems often experience inefficiencies due to friction, slippage, or backlash. Gear racks provide direct mechanical contact, minimizing slippage and ensuring that of the input energy from the pinion is transferred to linear motion.

Additionally, modern gear racks are manufactured with high-precision teeth and treated surfaces. This reduces friction between contacting surfaces, further improving efficiency. Lower friction not only saves energy but also reduces wear and extends the lifespan of the components.

Enhancing Load Capacity

Gear racks also contribute to mechanical efficiency by improving load handling. The engagement of multiple teeth distributes force across the rack, allowing the system to move heavier loads with less effort. Compared to alternative linear motion systems like screws or belts, gear racks can handle high loads more consistently and without excessive strain on individual components.

This even distribution of force reduces stress on the pinion and rack, minimizing deformation and maintaining accurate motion over time. In applications such as automated assembly lines or CNC machines, maintaining precise alignment under load is critical for efficiency and product quality.

Speed and Control Advantages

A gear and gear rack system allows precise control over speed and positioning. By selecting the appropriate gear ratio, operators can adjust the speed of linear movement without sacrificing torque or load capacity. This flexibility enhances overall mechanical performance, making it easier to optimize operations for specific tasks.

Furthermore, gear racks can operate quietly and smoothly when properly lubricated and aligned. Consistent motion reduces vibrations and energy loss, contributing to efficient and stable system performance.

Maintenance and Longevity

Efficient operation is closely tied to maintenance and durability. Gear racks require minimal upkeep when compared to chain or belt-driven systems, which can stretch or slip over time. Regular lubrication and inspection are typically sufficient to maintain performance.

Because the gear and gear rack system converts motion directly and reliably, less energy is wasted overcoming friction or compensating for mechanical play. This not only enhances immediate efficiency but also reduces long-term operational costs.

The gear and gear rack combination improves mechanical efficiency by providing direct motion transfer, reducing slippage, distributing load evenly, and allowing precise control over speed and positioning. Its low maintenance requirements and ability to handle high loads reliably make it a practical choice for many industrial and automation applications.