The Surface Heat Treatment Rack Pinion Gear is a precision-engineered component designed for a wide ...

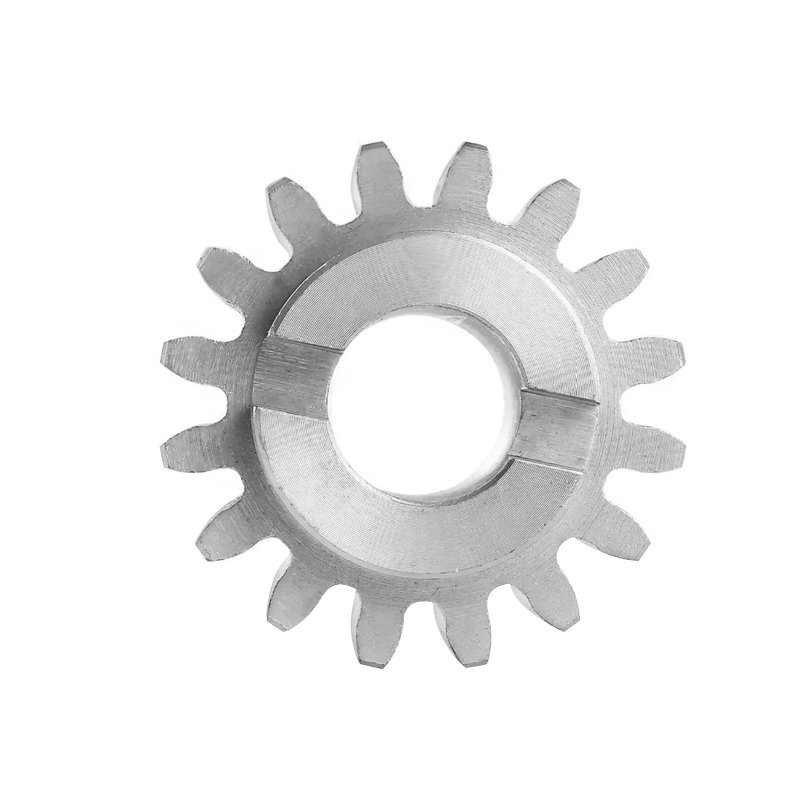

The Rack Pinion Gear is a fundamental mechanism widely used in various industrial applications to achieve precise linear motion control. It consists of two main components: the rack, which is a straight, flat bar with evenly spaced teeth along its length, and the pinion, a small gear that meshes with the rack. This combination allows for smooth and accurate movement along a linear path.

Construction and Design

The Rack Pinion Gear is designed to provide high precision and reliability. The rack is typically made from high-quality steel, ensuring durability and resistance to wear. The teeth on the rack are precision-cut to ensure a mesh with the pinion. The pinion, on the other hand, is usually a small cylindrical gear made from hardened steel. Its teeth are designed to engage seamlessly with those of the rack, providing smooth and continuous motion.

Applications

The Rack Pinion Gear is utilized in a wide range of industries due to its versatility and precision. In the automotive industry, it is a critical component in steering systems, where it converts the rotational motion of the steering wheel into the linear motion needed to turn the wheels. In machine tools, the Rack Pinion Gear is used to control the movement of cutting tools along a linear axis, ensuring precise machining operations. It is also commonly found in robotic arms, where it helps to achieve accurate positioning and movement. Additionally, the Rack Pinion Gear is used in conveyor systems, elevators, and other applications where linear motion control is required.

Advantages

The Rack Pinion Gear offers several advantages over other linear motion systems. One of the primary benefits is its high precision. The meshing of the rack and pinion ensures that the linear motion is accurate and repeatable, making it ideal for applications where tight tolerances are required. Another advantage is its high load capacity. The design of the Rack Pinion Gear allows it to handle significant forces, making it suitable for heavy-duty applications.

Maintenance and Lubrication

To ensure the good performance and longevity of the Rack Pinion Gear, proper maintenance and lubrication are essential. The teeth of the rack and pinion should be kept clean and free of debris to prevent wear and ensure smooth operation. Regular inspection of the components for signs of wear or damage is also important. Lubrication is crucial for reducing friction and wear between the rack and pinion.

Selection Criteria

When selecting a Rack Pinion Gear for a specific application, several factors need to be considered. The load capacity of the gear is an important consideration, as it must be able to handle the forces required for the application. The precision of the gear is also critical, especially in applications where tight tolerances are required. The size and dimensions of the Rack Pinion Gear should be compatible with the available space in the system.

The Rack Pinion Gear is a versatile and reliable component that provides precise linear motion control. Its high precision, durability, and ease of maintenance make it suitable for a wide range of applications. With proper selection, installation, and maintenance, the Rack Pinion Gear can provide long-lasting and accurate performance in various industrial and mechanical systems.

The Surface Heat Treatment Rack Pinion Gear is a precision-engineered component designed for a wide ...

The Stainless Steel Rack Pinion Gear for Sliding Motors is a high-precision component designed to pr...

The CNC (Computer Numerical Control) machine tools are widely used in the manufacturing and machinin...

The Sliding Doors Steel Rack Pinion Gear is a critical component in various sliding door systems, an...

The multiple sizes high precision rack pinion gear system is an essential mechanical solution for in...

The Stainless Steel Stepped Rack Pinion Gear is a highly versatile and durable mechanical component ...

The High Precision Straight Teeth Rack Pinion Gear is a critical component in various mechanical sys...

Product IntroductionThe Black Rust-Proof Straight Teeth Rack Pinion Gear is a high-quality mechanica...

The Smooth Surface High Precision Rack Pinion Gear is a high-performance mechanical component design...

The Rack Pinion Gear for automatic door openers is a crucial component in the operation of modern au...

The Multiple Specifications Rack Pinion Gear is a versatile mechanical component designed to meet a ...

The rust-proof high-precision rack pinion gear is a critical component designed for various industri...

Gate hinges are often overlooked, but they play a crucial role in ensuring smooth operation, security, and durability for both residential and industrial gates...

READ MORE

Doors, especially heavy or automated ones, require precise and reliable movement to operate safely and efficiently. A Gear And Rack mechanism is a widely used ...

READ MORE

Heavy gates are widely used in industrial sites, residential compounds, farms, and commercial properties. Their size and weight provide security and durability...

READ MORE

Sliding wheels are essential components used in furniture, machinery, doors, and industrial equipment. A Sliding Wheel Factory focuses on producing wheels that...

READ MORE